Vapor Recovery and Fugitive Emission Systems

GENERON® has developed a full line of Vapor Recovery solutions which allows the end user to turn their BTU rich waste products into a viable revenue stream while maintaining compliance with strict environmental regulations.

GENERON’s years of project management and engineering services experience, combined with our years of development and research allows us to treat a wider range of chemicals and offer an option for recovery other than combustion for tank and truck loading facilities.

GENERON®, along with our wholly-owned ACFM group, has significant experience in hydrocarbon recovery systems. More than 100 large units have been installed in petrochemical applications to recover butane, pentane, hexane and other hydrocarbons. Hundreds of units have been installed for gasoline vapor recovery at retail gasoline stations, and as a vapor recovery system for truck loading stations.

The VRU is designed specifically to offer a more feasible way to treat vapors that are not compatible with a carbon-based system. The membrane’s separation efficiency is custom designed for each application.

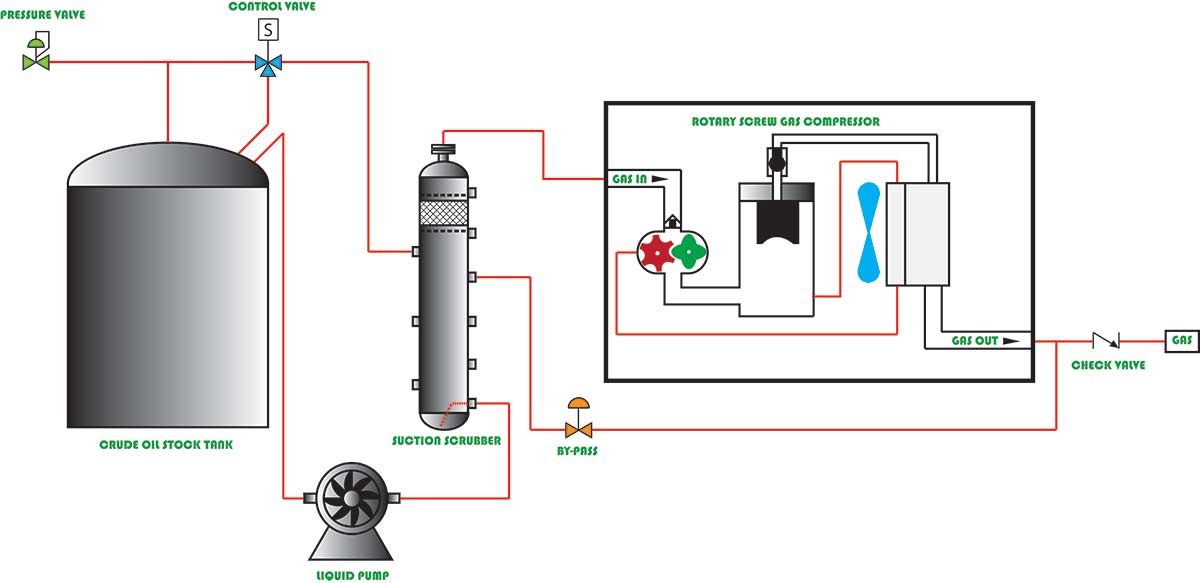

- Vapor Recovery Compressors (VRU)

- 5-100 horsepower

- 10-10,000 MCFD

- Electric or Engine Drive

- Natural Gas Liquid Recovery (NGLs)

- Separation Products

- Power Generation Equipment

FEATURING

- A better alternative for plants that handle petro-chemicals & chemicals.

- Compatible with a wider range of hydrocarbons & various crudes.

- Compact design; a smaller footprint compared to the equal sized carbon system.

- Steady state process for constant flow design applications.

- Fewer moving parts & control requirements compared to other technologies.

- Inlet compressor eliminates process pressure drop issues; inherently safe design.

APPLICATIONS

- Truck loading

- Marine loading

- Rail loading

- Tank breathing applications

- Petrochemical

STANDARD FEATURES

- All PLC shutdowns are tabularized and stored

- Electrical equipment built to local or EU standards

- Controls and drives

- Variable speed drive absorbent return pump

| Max Inlet Pressure – psi: 50, bar: 3.45 | ||||||||||||||

| Max Discharge Pressure – psi: 210, bar: 14.5 | ||||||||||||||

| Model | Power | Drive | Type | Flow Rate (at 105 PSIG/3.5BARG ) | Dimension | Weight | ||||||||

| Length | Width | Height | ||||||||||||

| hp | kw | scfm | nm3/hr | inch | mm | inch | mm | inch | mm | lbs | kg | |||

| GVRC-E05 | 5 | 3.7 | ELECTRIC | BELT | 21 | 36 | 86 | 2184 | 86.5 | 2197 | 80 | 2032 | 1275 | 580 |

| GVRC-E10 | 10 | 7.5 | ELECTRIC | BELT | 38 | 65 | 86 | 2184 | 86.5 | 2197 | 80 | 2032 | 1400 | 636 |

| GVRC-E15 | 15 | 11 | ELECTRIC | BELT | 55 | 94 | 86 | 2184 | 86.5 | 2197 | 80 | 2032 | 1560 | 709 |

| GVRC-E15D | 15 | 11 | ELECTRIC | DIRECT | 55 | 94 | 86 | 2184 | 86.5 | 2197 | 80 | 2032 | 1560 | 709 |

| GVRC-E20D | 20 | 15 | ELECTRIC | DIRECT | 71 | 120 | 86 | 2184 | 86.5 | 2197 | 80 | 2032 | 1720 | 782 |

| GVRC-E25D | 25 | 19 | ELECTRIC | DIRECT | 95 | 161 | 86 | 2184 | 86.5 | 2197 | 80 | 2032 | 1800 | 818 |

| GVRC-E30D | 30 | 22 | ELECTRIC | DIRECT | 118 | 200 | 86 | 2184 | 86.5 | 2197 | 80 | 2032 | 1960 | 891 |

| GVRC-E40D | 40 | 30 | ELECTRIC | DIRECT | 152 | 258 | 98 | 2489 | 86.5 | 2197 | 80 | 2032 | 2200 | 1000 |

| GVRC-E50D | 50 | 37 | ELECTRIC | DIRECT | 198 | 337 | 98 | 2489 | 86.5 | 2197 | 80 | 2032 | 2400 | 1091 |

| GVRC-E60D | 60 | 45 | ELECTRIC | DIRECT | 236 | 401 | 108 | 2743 | 86.5 | 2197 | 96 | 2438 | 2700 | 1227 |

| GVRC-E75D | 75 | 56 | ELECTRIC | DIRECT | 285 | 484 | 108 | 2743 | 86.5 | 2197 | 96 | 2438 | 3100 | 1409 |

| GVRC-E100D | 100 | 75 | ELECTRIC | DIRECT | 358 | 608 | 108 | 2743 | 86.5 | 2197 | 96 | 2438 | 3300 | 1500 |