What Is a VRU, and How Does a Vapor Recovery Unit Work?

June 25, 2019

In the downstream segment of oil and gas operations, it is critical to eliminate harmful vapors with potentially toxic and explosive properties from gasoline and other fuel types before the products are sold. Vapor recovery is particularly crucial as hydrocarbon storage containers may be prone to leaks via the hatches and safety valves as the internal vapor pressure builds up over time.

What Is Vapor Recovery?

Vapor recovery is the process of removing harmful vapor and fluid contaminants from crude products to improve the purity and prevent the release of toxic pollutants into the environment. Vapor removal is also done in chemical processing industries to recover unwanted vapors from storage units to keep the chemicals pure and safe for use and transport.

Is Vapor Removal Mandatory?

In different countries, vapor removal specifications are enacted by environmental protection authorities, mandated by law, and binding on all operators and producers involved in the processing and storage of petroleum, natural gas, and petrochemical products.

In the United States, The EPA mandates operators to carry out vapor removal to regulate harmful air emissions in natural gas processing plants, hydrocarbon storage facilities, and natural gas wells under the New Source Performance Standard 40 CFR, Part 60, Sub-part OOOO, also known as the ‘Quad O.’

Under this new regulation, operators must eliminate at least 95% of vapors produced in hydrocarbon storage units. The new standard places increased demand on oil and gas management to devise sustainable ways to mitigate vapor pressure in tanks and prevent costly emission releases. One of the most effective systems for vapor removal is the vapor removal unit (VRU).

What Is a VRU?

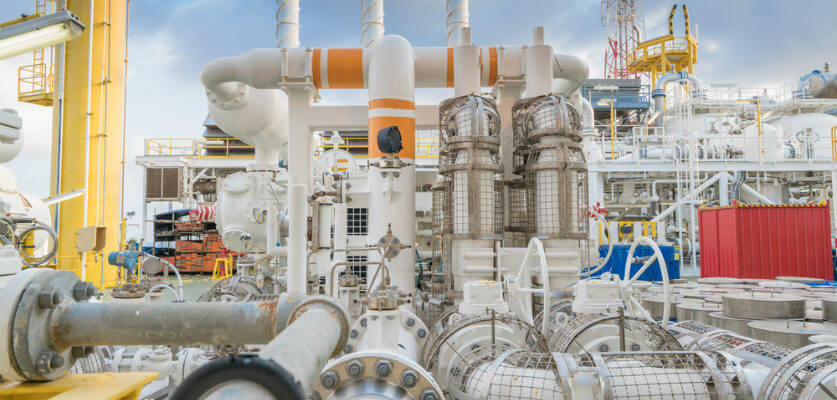

A Vapor Recovery Unit (VRU) is a set-up designed to remove unwanted vapors present in crude oil or distillate tanks allowing operators to comply with prevailing emission regulations. VRU systems can be employed in a wide range of chemical industries with several variants available. For example, a vapor recovery system for storage tanks can be used to recover vent gas from crude oil and distillate tanks at storage facilities.

Vapor Recovery Unit – How It Works

VRUs are mechanically driven and are powered by an electric motor or gas engine depending on what’s available. The VRU working principle is based on the Ideal gas law (PV = nRT or pressure x volume = gas mass x temperature x gas constant). In essence, when you compact your process gas into a smaller volume, the pressure of the gas increases.

The typical VRU consists of four principal components:

- Gas Compressor

- Scrubber

- Variable Frequency Drives (VFDs)

- Switching device

Gas compressor

Several types of vapor recovery compressor package may be used for vapor removal including flooded rotary screw, rotary sliding vane, and reciprocating piston compressors or any model which utilizes the principle of positive displacement.

Scrubber

The scrubber is a device used to remove fluid impurities from a natural gas flow stream. Scrubbers and fuel gas conditioning systems are an essential addition to VRUs for dealing with vapors in crude oil/distillate tanks with high BTU vent gas.

Variable Frequency Drives (VFDs)

The VFD is an electromechanical driver system whose primary function is to adjust the speed of the compressor depending on the rate of flow of gas into the VRU.

Switching Device

The switching mechanism in a VRU detects changes in pressure inside the tanks and activates the compressor. The primary function of the switch is to start and stop the operation automatically depending on the pressure conditions inside the tank.

How Does a Vapor Recovery Unit Work?

The primary function of a VRU system is to remove the vapors that collect inside sealed hydrocarbon tanks. The machine does this by gas compression and suction.

The vapor recovery procedure involves the following steps:

- The rotary screw gas compressor sucks liquid molecules into the scrubber

- The scrubber removes the water vapor, debris, and unwanted fluids from the tank.

- The recovered vapor is pumped into gas lines while the trapped liquids are channeled to the pipelines.

Use GENERON’s Vapor Recovery Solutions for all your recovery needs

With VRUs, industries can recover vent gas and other air pollutants safely, ensuring compliance with emission regulations. For the most efficient vapor recovery systems, use the services of an industrial gas solutions expert – GENERON.

GENERON Vapor Recovery Systems are ideal vapor recovery solutions for the petroleum and petrochemical industries. The technology utilizes the best membranes in the industry to treat a wide range of vapors in hydrocarbon and chemical storage units.