Nitrogen Generator Cabinets

For over 50 years GENERON® has been the world leader in the design and manufacture of Nitrogen Generators. GENERON® has supplied thousands of Nitrogen Generators, from cabinet to large containerized systems, around the world. These systems are energy efficient, have a 30% smaller footprint and are low maintenance. Our maintenance programs ensure your systems long term efficient operation.

The GENERON® Cabinet Series is ideal where low to medium Nitrogen flow rates are required in a small footprint. GENERON® Cabinet Series is designed and manufactured using the patented GENERON® Hollow Fiber Membranes. These highly engineered systems produce required flow rates in a small cabinet design with an average 30% smaller footprint utilizing less power.

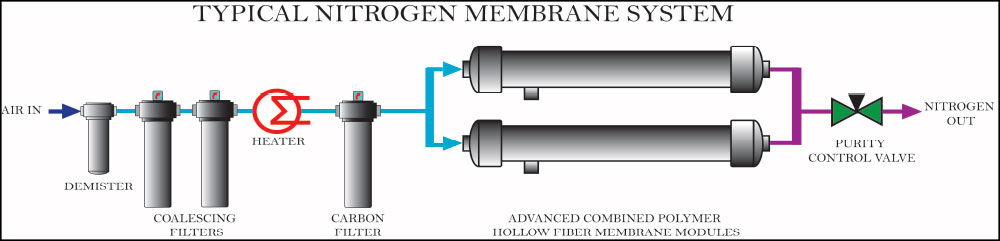

The GENERON® Membrane modules contain over a million fibers. In our GENERON® membrane nitrogen generators, compressed feed air is passed down the bores of the fibers at one end of the module, with enriched nitrogen product gas exiting from the opposite end. Oxygen and water vapor are selectively removed and vented from the feed air as it flows through the module.

Our ISO-9001, ASME, PED/PE, UL/CUL certified facilities and shops ensure the highest standards are met and your expectations exceeded.

Applications:

- Marine

- General Blanketing

- Refinaries

- Auto Clave

- Blanketing of Chemical & Pharmaceuticals

- Brazing

- Food Packaging

- Gas Assisted Injection Molding (GAIM)

- Heat Treatment of Ferrous & Non-Ferrous Metals

- Inerting of Flammable Liquids & Gases

- Cylinder Filling

Standard Features:

- .01 Micron Coalescing Filter with drain

- Activated Carbon Filter

- GENERON® Hollow Fiber Membranes

- Manual Purity Control Valve

- PLC Control System with HMI Feature

- Fail Safe Package (off –spec nitrogen auto-vented)

- NEMA 12 Cabinet Enclosure

- Inlet Pressure Gauge

- Outlet Pressure Gauge

- Oxygen Analyzer with Calibration Valve

- Pressure Safety Valve

- Lifting lugs

- Performance Test and Report

- Performance certificate

Optional Features:

- Demister / Moister Separator

- 1 Micron Coalescing Filter

- Process Heater

- Automatic Purity Control Valve

- NEMA 4X Control Cabinet Enclosure (316SS)

- Enhanced PLC with Telemetry

- Hazardous Area Classification

- Auto/Stand by Mode

- Product Flow Meter

- Dew Point Analyzer

- Primary Air Compression

- Sea-water cooled Air Compresso

- rNitrogen Booster Compressor for high pressure applications