GENERON® Membrane Modules for Air and Process Gas Separation

GENERON® membrane modules have been at the forefront of the industry for over 40 years. Our research and development team in California works to continually improve the performance and durability of our membranes.

GENERON® membrane modules have been at the forefront of the industry for over 40 years. Our research and development team in California works to continually improve the performance and durability of our membranes.

GENERON® Hollow Fiber Membrane Modules are manufactured and tested in its Pittsburg, California manufacturing facilities. Four different classification of Hollow Fiber Membrane Modules are produced at this facility. All offer the highest efficiency and flow rate.

- Nitrogen Membrane Modules

- Oxygen Membrane Modules

- Dehydration Membrane Modules

- Process Gas Membrane Modules

Technology

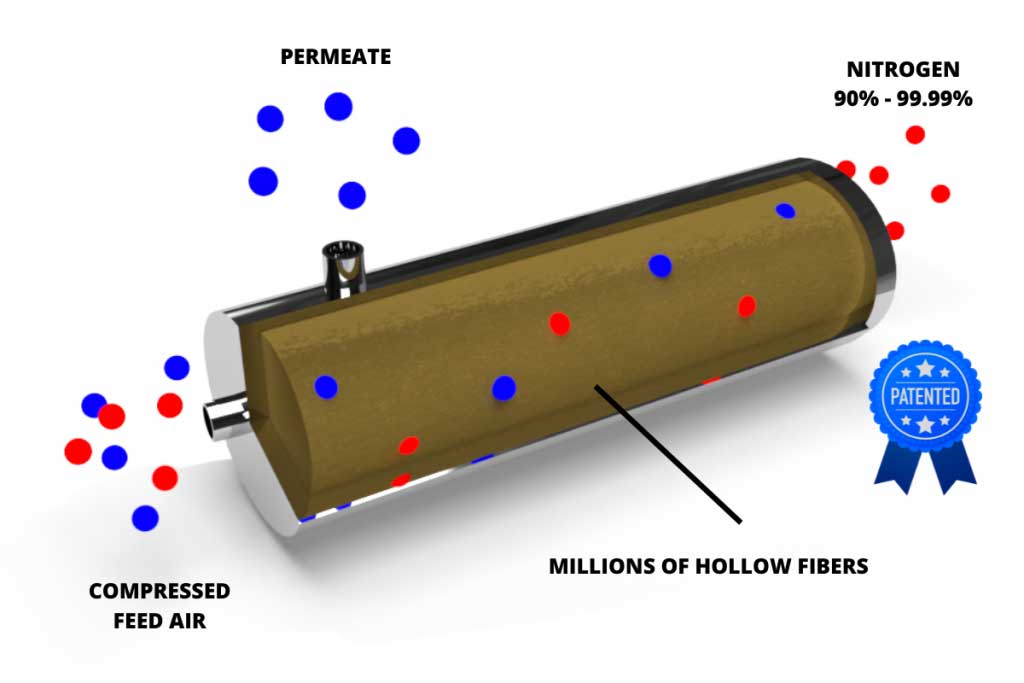

Each application design has a unique chemical formulation and production process for the individual module fibers. At the heart of the technology are polymeric membrane materials that allow for rapid passage of a single gas, while minimizing the passage of others, when applying a pressure gradient across the membrane.

Membrane materials are formed into hollow fibers to provide maximum surface area for the high gas volume processing rate often required. GENERON holds over 100 patents on the design, packaging, and formulation of these hollow fiber membranes. The fibers are bundled into modules of various lengths and diameters to meet very specific flow rates and separation requirements. Typical modules have anywhere from a half a million, to over a million fibers in one bundle.

Two types of Module configurations are currently offered:

- Bore-Side Feed – The vast majority of membrane applications use a Bore-Side feed configuration. In this process, the incoming gas/air is directed down the center of the module fiber. The product gas exits the opposite end of the fiber, where it can be collected or diverted into a process application. The waste or unwanted gas passes through the wall of the fiber and exits the module through a side port, where it can be collected, diverted, or allowed to exhaust back into the atmosphere. This type of membrane module is utilized in applications where the feed pressure is less than 500 psig (34 bar).

- Shell-Side Feed – Shell-side feed modules operate by a similar principle as bore-side feed modules, except the incoming gas or air enters the module through a side port on the outer shell, allowing it to flow onto the outside of the fibers. The gas then preferentially permeates the fiber wall and flows down the center of fiber, where it exits the fiber bundle at the end of the module. The gas that does not permeate the wall of the fiber flows along the outside of the fibers, where it is exits through a collection plate at the opposite end of the module. This type of module is used for high pressure applications, 1200 psig (83 bar), and almost exclusively for hydrocarbon separations such as CO2 , CH4 , H2 , etc.

Higher volumetric flow. Higher selectivity. Lower CAPEX. Lower OPEX.

In addition to our GENERON® Membrane Systems, we offer a variety of sizes of Nitrogen, Dehydration and Process Gas membranes®. We can meet any flow demand and environment for most applications.

GENERON® Membrane Module – Video

GENERON ISO 9000, ASME, PED, GOST and UL 508A/CSA-C22.2 certified manufacturing facilities and plants in Texas and California ensure the highest-standard products on the market.