Compressor Packaging

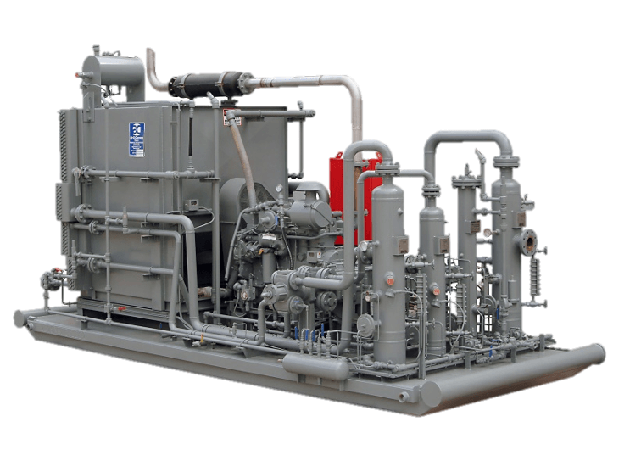

The GENERON Compression group packages a large array of compressor brands as well as technologies.

- Oil Flooded Rotary Screw

- Sliding Vane

- Oil Free

- Reciprocating

The brand and type of compressor is application and customer driven. Our compression group handles packages from fractional HP to 5,000 HP and discharge pressures to 5,000 psig.

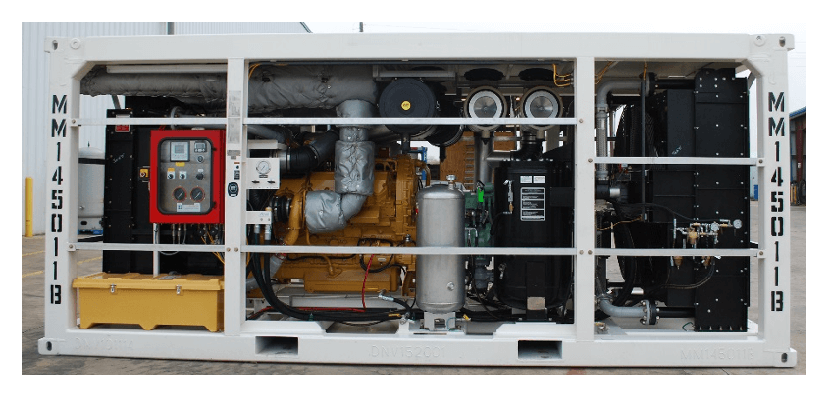

GENERONhas built multiple portable Compression Systems that are Diesel Driven. Systems are typically supplied in DNV Certified Frames for both oil flooded rotary screw (to 500 PSIG) and reciprocating compressors to 5,000 PSIG.

GENERON Compression Packages have been manufactured for the following gases:

- Air

- Nitrogen

- Natural Gas

- Hydrogen

- Helium

- Syngas

- Process Gas Blends

GENERON’s in-house pressure vessel company, Houston Vessel Manufacturing (HVM), is an ASME / PED certified shop and can custom build any tank or separator required for the application. Additionally, our in-house UL Certified electrical panel shop can custom make control cabinets. Our in-house programmers can customize Allen Bradley, Siemens, or any other PLC’s to meet the customer specific requirements

Our Compression packages are typically supplied with additional equipment:

- Interconnecting piping

- Wet air receivers

- Compressed Air-Drying technologies (Refrigerated, and Twin Tower Desiccant Dryers)

- Dry Air receivers – if supplied with a dryer

- Condensate removal and collection systems

All of our systems are fabricated and fully tested in our Houston, Texas ISO 9000 certified facility. We have in house power for up to 2,000 HP at 60 cycle. Additionally, we bring in auxiliary power for systems that use 50 cycle or specific voltages.Our team has extensive experience to handle your every compression requirement.

The following is just a sample of the type of systems we have done for our customers:

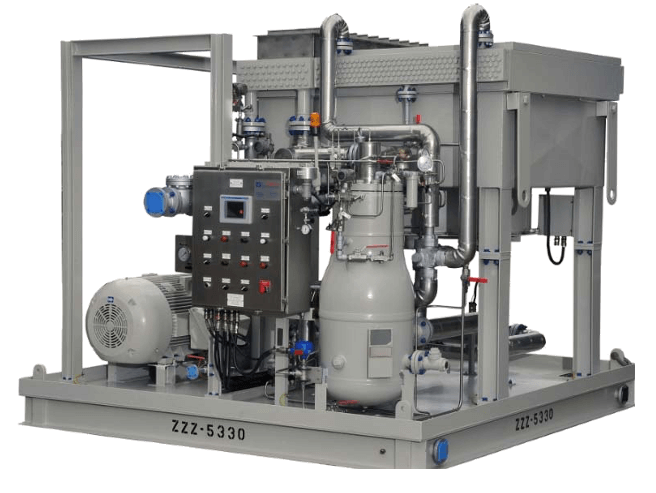

3 x 50% Air Compressor

3 x 50% Air Compressor

Capacity: 815 cfm (1290Nm3/h)

Pressure: 150 psig (10.3barg)

Type: Rotary Screw Oil Flooded

Location: Offshore – Gulf of Mexico

Area Class: Class I, Div. 2

Application: Platform Instrument Air

2 x 100% Air Compressor

2 x 100% Air Compressor

Capacity: 300 cfm (475Nm3/h)

Pressure: 175 psig (12barg)

Type: Rotary Screw Oil Flooded

Location: Offshore – Africa

Area Class: Class I, Div. 2

Application: Platform Instrument Air

2 x 100% Air Compressor

2 x 100% Air Compressor

Capacity: 140 cfm(221Nm3/h)

Pressure: 175 psig (12barg)

Type: Rotary Screw Oil Flooded

Location: Offshore – Gulf of Mexico

Area Class: Class I, Div. 2

Application: Platform Instrument Air

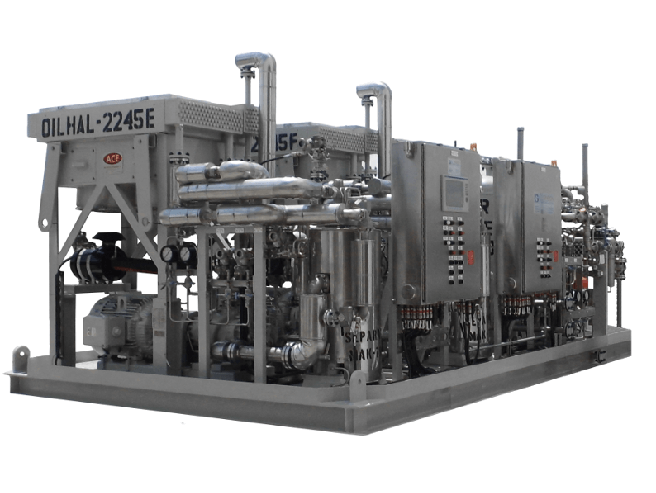

Offshore Air Compression

Offshore Air Compression

Capacity: 800 cfm (1266Nm3/h)

Pressure: 175 psig (12barg)

Type: Rotary Screw Oil Flooded

Location: Offshore – Israel

Area Class: IEC Ex D

Application: Platform Instrument Air

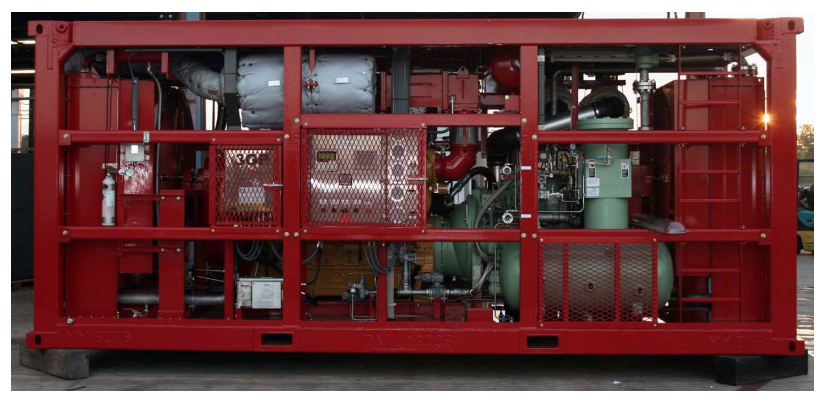

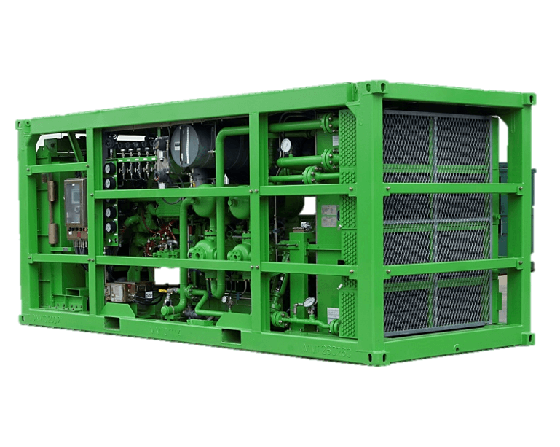

Portable Air Compression

Portable Air Compression

Capacity: 1800 cfm (2849Nm3/h)

Pressure: 350 psig (24barg)

Type: Rotary Screw Oil Flooded

Location: Worldwide

Area Class: Class 1 Div. 2

Certification: DNV 2.7-1

Application: Nitrogen Generation

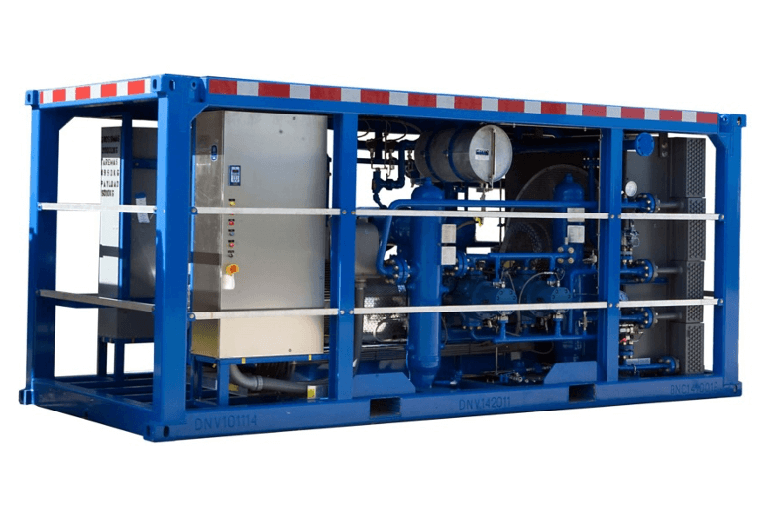

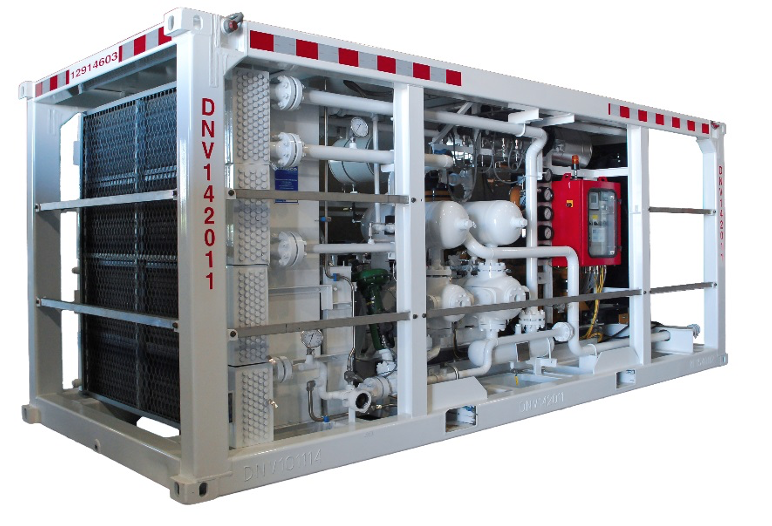

Portable Air Compression

Portable Air Compression

Capacity: 1500 cfm (2375Nm3/h)

Pressure: 500 psig (34barg)

Type: Rotary Screw Oil Flooded

Location: Worldwide

Area Class: ATEX Zone 2

Certification: DNV 2.7-1

Application: Nitrogen Generation

Oil Free Compressor

Capacity: 299 cfm (473Nm3/h)

Pressure: 145 psig (10barg)

Type: Rotary Screw Oil Free

Location: Onshore – Iraq

Area Class: Non Hazardous

Driver: Electric Motor

Application: Instrument Air and Nitrogen Generation

GENERON offers 20hp to 500hp, (15.kw—373kw) Industry proven engineered rotary screw compression packages built to any technical specification either engine or electric drive, for moving large volumes at lower suction with discharge pressures up to 155psig, (10.7barg).

BOOSTER COMPRESSOR PACKAGES

Reciprocating Compressor Packages

OIL FLOODED Reciprocating Type

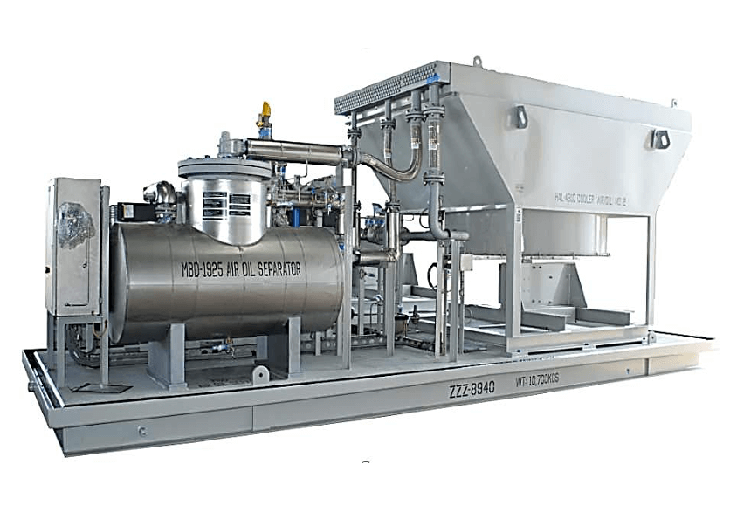

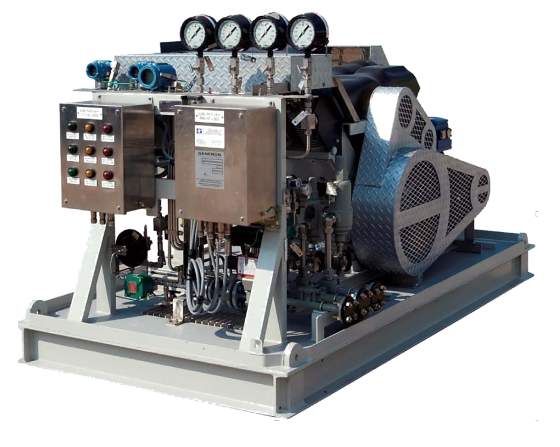

Portable Booster Compressor

Portable Booster Compressor

Capacity: 1500 scfm (2375Nm3/h)

Pressure: 5000 psig (345barg)

Type: Reciprocating Oil Lubricated

Location: Worldwide

Area Class: Class 1 Div. 2

Certification: DNV 2.7-1

Driver: Electric Motor

Application: Nitrogen Injection

Portable Booster Compressor

Portable Booster Compressor

Capacity: 2000 scfm (3166Nm3/h)

Pressure: 5000 psig (345barg)

Type: Reciprocating Oil Lubricated

Location: Worldwide

Area Class: ATEX Zone 2

Certification: DNV 2.7-1

Driver: Diesel Engine

Application: Underbalance Drilling

Portable Booster Compressor

Portable Booster Compressor

Capacity: 3000 scfm (4749Nm3/h)

Pressure: 5000 psig (345barg) Type: Reciprocating Oil Lubricated

Location: Worldwide

Area Class: ATEX Zone 2

Certification: DNV 2.7-1

Driver: Diesel Engine

Application: Oil Field Services

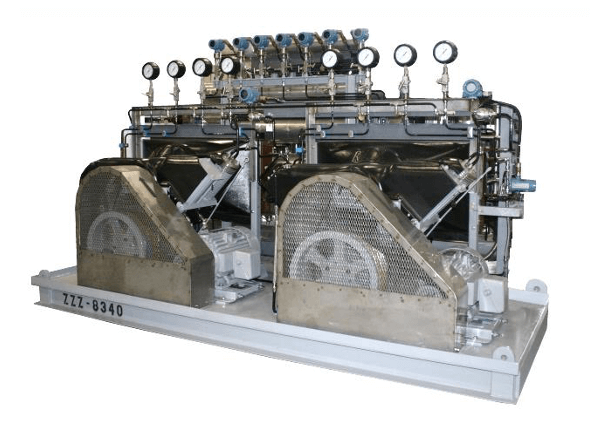

Offshore Booster Compressor

Offshore Booster Compressor

Capacity: 20 scfm (32Nm3/h)

Pressure: 2200 psig (150barg)

Type: Reciprocating Oil Free

Location: Onshore – Indonesia

Area Class: Non Hazardous

Driver: Electric Motor

Application: Plant High Pressure Nitrogen

Offshore Booster Compressor

Offshore Booster Compressor

Capacity: 17scfm (27Nm3/h)

Pressure: 3400 psig (234barg)

Type: Reciprocating Oil Free

Location: Offshore- Gulf of Mexico

Area Class: Class I Div. 2

Driver: Electric Motor

Application: Platform High Pressure Nitrogen

Offshore Booster Compressor

Offshore Booster Compressor

Capacity: 40scfm (63Nm3/h)

Pressure: 2700 psig (186barg)

Type: Reciprocating Oil Free

Location: Offshore- Africa

Area Class: Class I Div. 2

Driver: Electric Motor

Application: Platform High Pressure Nitrogen

Oil Free Reciprocating Type

GENERON can design an air or gas compressor system to your individual application requirements & customer specifications. By utilizing various compressor manufacturers such as; Sullair, Gardner Denver, Kaeser, LeROI, GE, Ariel, IR, Sullivan Palatek, and others, our engineers can select the best solution for your project needs and work with you to supply the most cost effective solution.

At GENERON, our engineering, design, and fabrication departments are all under one roof, in our ISO-9000 facility. This not only allows us to be extremely competitive, it allows the easy mitigation of environmental or design changes to be approved and made on the spot.

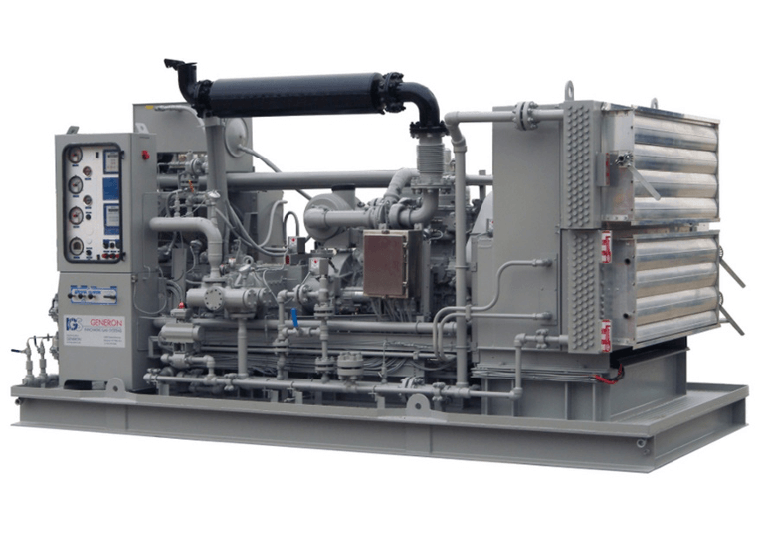

PROCESS GAS COMPRESSION

GENERON can design and build a gas compressor system to the individual application requirements and to stringent customer specifications. By use of various compressor manufacturers, such as LeROI, GE, and Ariel, our engineers & designers can work to your requirements to select the best and most cost-effective solution for your project needs.

GENERON® Gas Compressor Package, utilizing a GE-CFH62 Gas Compressor 2350 scfm (3720 Nm3/hr) Capacity @ 1100 psig (76 barg) Discharge Pressure√

N2 Booster Compressor

N2 Booster Compressor

Capacity: 966scfm (1530Nm3/h)

Pressure: 5000 psig (345barg)

Location: Onshore – USA

Area Class: Non Hazardous Area

NG Compression Package

NG Compression Package

Capacity: 514scfm (813Nm3/h)

Pressure: 750psig (52barg)

Location: Onshore – USA

Area Class: Class 1 Div. 2

NG Compression Package

NG Compression Package

Capacity: 417scfm (660Nm3/h)

Pressure: 1000psig (69barg)

Location: Onshore – USA

Area Class: Class 1 Div. 2

VRU Compression Package

VRU Compression Package

Capacity: 1042scfm (1621Nm3/h)

Pressure: 60psig (4barg)

Location: Offshore – Nigeria

Area Class: Class 1 Div. 2

Examples of Complete Systems

GENERON’s fully equipped manufacturing and testing facilities provides the flexibility to work with complete large packages and perform FAT testing prior to shipment.

Instrument Air Package

INSTRUMENT AIR PACKAGE

IA Capacity: 1750 cfm (2770Nm3/h)

Pressure: 150 psig (10.3barg)

Pressure Dew Point: -40°F (-40°C)

Equipment: 3 Air Compressors & 1 Desiccant Air Dryer

MEMBRANE NITROGEN PACKAGE

N2 Capacity: 266scfm (421Nm3/h)

Pressure: 125 psig (8.6barg)

N2 Purity: 95%

Equipment: NEMA4X Nitrogen Membrane Cabinet

Area Class: Zone 2 ExDe

Location: Onshore – Nigeria

Instrument Air Package

INSTRUMENT AIR PACKAGE

IA Capacity: 6720 cfm (10638Nm3/h)

Pressure: 145 psig (10barg)

Pressure Dew Point: 39°F (4°C)

Equipment: 4 Air Compressors & 2 Refrigerated Air Dryers

MEMBRANE NITROGEN PACKAGE

N2 Capacity: 2650scfm (4195Nm3/h)

Pressure: 130 psig (8.9barg)

N2 Purity: 95%

Equipment: Membrane Skidded Nitrogen Generator

Area Class: Non-Hazardous

Location: Onshore – Nigeria

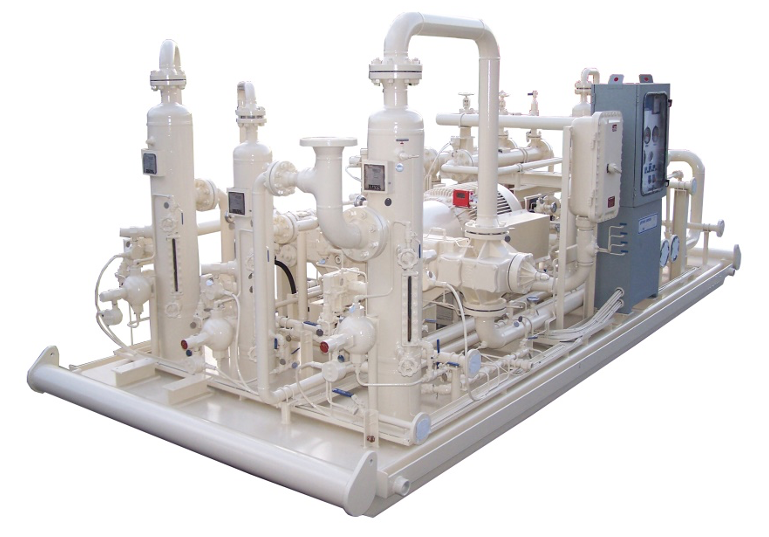

Air Compression Package

AIR COMPRESSION PACKAGE

Primary Compression Capacity: 8835 cfm (13986Nm3/h)

Discharge Pressure: 350 psig (24barg)

Equipment: 5ea. Rotary Screw Oil Flooded Air Compressors

MEMBRANE NITROGEN PACKAGE

N2 Capacity: 3750 scfm (5936Nm3/h)

Pressure: 300 psig (20.6barg)

N2 Purity: 95%

Equipment: 5ea. NPU Nitrogen Membrane Generators

N2 BOOSTER COMPRESSION PACKAGE

Booster Compression Capacity: 3750 scfm (5936Nm3/h)

Discharge Pressure: 5000 psig (345barg)

Equipment: 5ea. Reciprocating Booster Compressors

Area Class: ATEX Zone 2

Location: Offshore – Brazil