PSA Nitrogen Generator, Twin Tower Systems

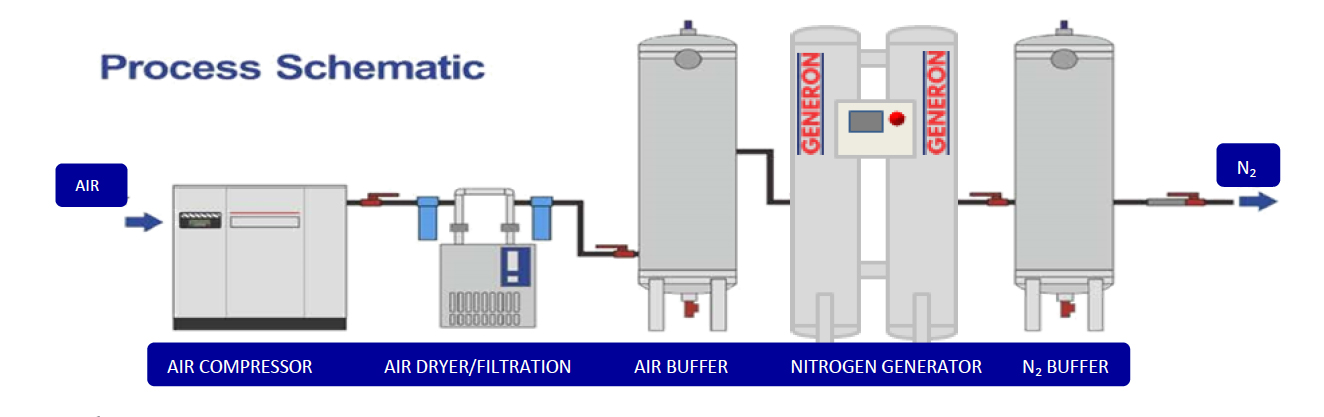

GENERON® Nitrogen PSA Generators separate nitrogen from compressed air utilizing Pressure Swing Adsorption (PSA) technologies. Compressed air, which consists of approximately 21% oxygen and 78% nitrogen, is passed through a bed of Carbon Molecular Sieve (CMS). The CMS preferentially adsorbs O2 and moisture, allowing the N2 to pass through as a product gas at the specified pressure. While one of the towers is in the adsorption phase, the other tower is being regenerated, by de-pressurizing and allowing the CMS to release the adsorbed gases to the atmosphere. The cycle then repeats, allowing for constant flow of a controlled Nitrogen purity and flow.

This product line is designed for medium to large flow rates and has a reduced footprint. It consists of single pairs of our Twin Tower Adsorber Vessels and air and nitrogen buffer vessels (installed on a common skid or supplied separately).

Standard Features:

- ASME Adsorber Vessels

- High Cycle Life Pneumatic / Electric Valves

- Oxygen Analyzer with calibration kit

- Pressure Safety Valve

- Nitrogen Pressure Regulator

- PLC Control System

- Carbon Steel Skid

- Exhaust Silencing Muffler

- Highest Performance Adsorbent Media

Options / Upgrades

- Inlet Filtration Package

- Post Filtration Package

- Product Flow Meter

- Auto Shut Down/Startup/Standby Mode

- Off Specification Circuit

- HMI Display Screen

- Compressed Air Buffer Tank

- Nitrogen Buffer Tank

- Master Controller driven for multiple unit operation

- Enhanced PLC with Telemetry

- Dew Point Analyzer

- Energy Saving Part-Load Control

Advantages:

- Low Gas Generating Cost

- Low Energy Consumption

- Fully Automatic Unattended Operation

- Highly Reliable

- Easy Installation

- Low Maintenance

- Heavy Duty Construction

- No Hazardous Storage

- Low dBa Levels

| NITROGEN PURITY / FLOW RATE | ||||||||||||||||||||||||

| PSA Model | 97% | 99% | 99.9% | 99.99% | 99.999% | Approx. Weight and Dimensions | ||||||||||||||||||

| SCFH | Nm3/h | SCFH | Nm3/h | SCFH | Nm3/h | SCFH | Nm3/h | SCFH | Nm3/h | H | W | L | Weight | |||||||||||

| Inlet P (PSIG) | 90 | 145 | 90 | 145 | 90 | 145 | 90 | 145 | 90 | 145 | 90 | 145 | 90 | 145 | 90 | 145 | 90 | 145 | 90 | 145 | Inch | Inch | Inch | Lbs. |

| Inlet P (Barg) | 6.2 | 10 | 6.2 | 10 | 6.2 | 10 | 6.2 | 10 | 6.2 | 10 | 6.2 | 10 | 6.2 | 10 | 6.2 | 10 | 6.2 | 10 | 6.2 | 10 | ||||

| NS-20-78 | 6188 | 10548 | 163.3 | 278.3 | 4552 | 7489 | 120.1 | 197.6 | 2616 | 3903 | 69.0 | 103.0 | 1770 | 2122 | 46.7 | 56.0 | 933 | 766 | 24.6 | 20.2 | 110 | 52 | 58 | 3851 |

| NS-20-93 | 7378 | 12574 | 194.7 | 331.8 | 5441 | 8928 | 143.6 | 235.6 | 3128 | 4653 | 82.5 | 122.8 | 2115 | 2530 | 55.8 | 66.8 | 1115 | 913 | 29.4 | 24.1 | 110 | 50 | 54 | 4228 |

| NS-24-75 | 8685 | 14799 | 229.2 | 390.5 | 6372 | 10507 | 168.1 | 277.2 | 3662 | 5476 | 96.6 | 144.5 | 2477 | 2977 | 65.4 | 78.5 | 1306 | 1075 | 34.5 | 28.4 | 97 | 54 | 60 | 4592 |

| NS-24-85 | 9832 | 16755 | 259.4 | 442.1 | 7255 | 11896 | 191.4 | 313.9 | 4170 | 6200 | 110.0 | 163.6 | 2820 | 3371 | 74.4 | 88.9 | 1487 | 1217 | 39.2 | 32.1 | 118 | 54 | 60 | 5378 |

| NS-30-68 | 12446 | 21209 | 328.4 | 559.6 | 9103 | 15058 | 240.2 | 397.3 | 5232 | 7848 | 138.0 | 207.1 | 3538 | 4267 | 93.4 | 112.6 | 1865 | 1541 | 49.2 | 40.7 | 103 | 72 | 72 | 6909 |

| NS-30-81 | 14839 | 21209 | 391.5 | 559.6 | 10924 | 15058 | 288.2 | 397.3 | 6279 | 7848 | 165.7 | 207.1 | 4246 | 4267 | 112.0 | 112.6 | 2238 | 1541 | 59.1 | 40.7 | 121 | 72 | 72 | 7576 |

| NS-36-74 | 19693 | 33557 | 519.6 | 885.4 | 14524 | 23826 | 383.2 | 628.7 | 8348 | 12417 | 220.3 | 327.6 | 5645 | 6751 | 148.9 | 178.1 | 2976 | 2438 | 78.5 | 64.3 | 116 | 74 | 88 | 9370 |

| NS-36-95 | 25266 | 43053 | 666.6 | 1136.0 | 18570 | 30568 | 490.0 | 806.5 | 10674 | 15931 | 281.6 | 420.3 | 7218 | 8662 | 190.4 | 228.5 | 3805 | 3127 | 100.4 | 82.5 | 137 | 74 | 88 | 10882 |

| NS-42-83 | 30216 | 51490 | 797.3 | 1358.6 | 22211 | 36558 | 586.0 | 964.6 | 12766 | 19053 | 336.8 | 502.7 | 8634 | 10359 | 227.8 | 273.3 | 4551 | 3740 | 120.1 | 98.7 | 135 | 84 | 112 | 15238 |

| NS-48-74 | 34987 | 59667 | 923.1 | 1574.3 | 25805 | 42364 | 680.9 | 1117.8 | 14832 | 22079 | 391.3 | 582.6 | 10030 | 12004 | 264.6 | 316.7 | 5288 | 4334 | 139.5 | 114.4 | 127 | 90 | 112 | 15602 |

| NS-48-85 | 40173 | 68457 | 1060.0 | 1806.3 | 29494 | 48605 | 778.2 | 1282.5 | 16952 | 25331 | 447.3 | 668.4 | 11464 | 13772 | 302.5 | 363.4 | 6044 | 4973 | 159.5 | 131.2 | 138 | 90 | 112 | 16360 |

| NS-48-94 | 44433 | 75715 | 1172.4 | 1997.8 | 32771 | 53758 | 864.7 | 1418.4 | 18836 | 28017 | 497.0 | 739.2 | 12738 | 15233 | 336.1 | 401.9 | 6715 | 5500 | 177.2 | 145.1 | 147 | 90 | 112 | 16699 |

| NS-60-68 | 50683 | 86366 | 1337.3 | 2278.8 | 37140 | 61320 | 979.9 | 1617.9 | 21347 | 31958 | 563.2 | 843.2 | 14436 | 17375 | 380.9 | 458.4 | 7611 | 6274 | 200.8 | 165.5 | 121 | 120 | 156 | 19988 |

| NS-60-74 | 50683 | 86366 | 1337.3 | 2278.8 | 37140 | 61320 | 979.9 | 1617.9 | 21347 | 31958 | 563.2 | 843.2 | 14436 | 17375 | 380.9 | 458.4 | 7611 | 6274 | 200.8 | 165.5 | 127 | 120 | 156 | 20791 |

| NS-60-81 | 55178 | 94025 | 1455.9 | 2480.9 | 40782 | 66759 | 1076.0 | 1761.5 | 23440 | 34792 | 618.5 | 918.0 | 15852 | 18916 | 418.3 | 499.1 | 8357 | 6830 | 220.5 | 180.2 | 184 | 120 | 156 | 21774 |

| NS-60-88 | 60364 | 102862 | 1592.7 | 2714.0 | 44423 | 72872 | 1172.1 | 1922.7 | 25533 | 37979 | 673.7 | 1002.1 | 17267 | 20649 | 455.6 | 544.8 | 9103 | 7456 | 240.2 | 196.7 | 184 | 120 | 156 | 25515 |

| NS-60-94 | 65550 | 111699 | 1729.6 | 2947.2 | 48064 | 79307 | 1268.2 | 2092.5 | 27626 | 41332 | 728.9 | 1090.6 | 18682 | 22472 | 492.9 | 592.9 | 9849 | 8114 | 259.9 | 214.1 | 184 | 120 | 156 | 28016 |

| Flow and pressure values are averages throughout a cycle with tolerances of ±3%. Performance data based on 68°F (20°C) PSA inlet temperature. Standard conditions: 68°F (20°C) and 14.7 psi (1 atm). Custom sizes are available upon request. | ||||||||||||||||||||||||