Syngas Hydrogen (H2) and Carbon Monoxide (CO) Ratio Adjustment

Syngas (H2 + CO + others) is used to produce a variety of products. Each product requires a specific ratio of H2 to CO in the process feed gas to optimize production yields. Feed streams too rich in H2 can be adjusted by using membranes to selectively strip out the excess H2. The H2:CO ratio can be optimized effectively using GENERON® membrane systems.

GENERON® will boost the yields through system designs and blending schemes that take full advantage of GENERON® membrane modules for high selectively for H2. The vented off-gas of H2 can be at purities over 96%. Control of the process is simple with multiple membrane filters controlled by a single flow control valve.

Depending on the feed composition, one can purify CO with GENERON® membrane to over 95% with greater than 90% CO yields. If higher purities are required and/or if nitrogen is present in the CO rich feed gas, GENERON‘s PSA nitrogen generator (pressure swing adsorption) can be used to achieve purities up to 99.99%.

The GENERON® Advantage

- Extensive Experience – custom designed skids

- State-of-the-art Membrane – high recoveries

- Simple Solution – no moving parts, minimal maintenance

- Engineering support from concept to completion

- Remote Operation – Minimal attention required, fully automated systems

- Minimal Losses – low H losses

- No Chemicals – environmentally friendly

- Small Footprint – easily meet footprint requirements

TYPICAL APPLICATIONS

- Biomass-to-Liquid (BTL) biofuels production

- CO purification

- FCC overhead gas

- Gas-to-liquid fuel production

- H2:CO ratio adjustment in syngas

- Hydro-cracker purge gas

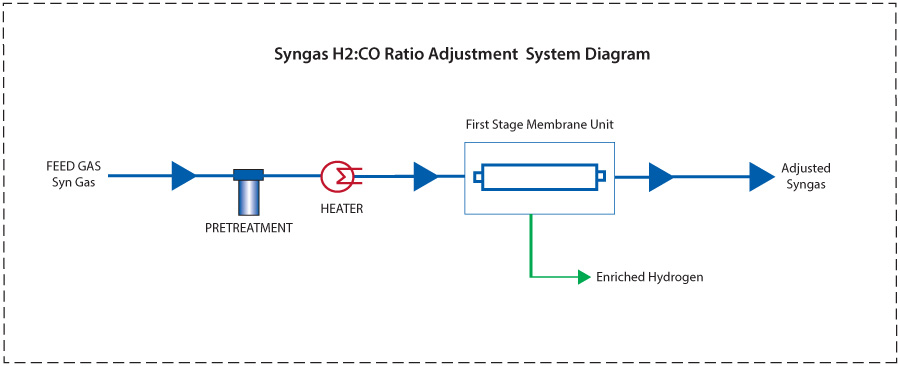

In a typical GENERON® membrane system for H2:CO ratio adjustment, the feed gas is filtered to remove particles and condensate and then heated to an optimum operation temperature and ready to enter the GENERON® membrane filters. Hydrogen gas permeates through the membrane walls creating a hydrogen rich permeate stream. CO2 and H2O, as well as H2S, are enriched in the permeate stream and may be lowered by this same process. The hydrogen-reduced CO richer product gas remains at pressure in the non-permeate (“retentate”) stream.

System Performance

- Feed gas pressures up to 500 psig (34.5 barg)

- Flow rates to 100 MMSCFD

- >90% CO Recovery

- 99.9% to 99.99+% purity with PSA technology

- CO+H2 purities to 95%