Sequential PSA Nitrogen Generator

Sequential PSA Nitrogen Generator

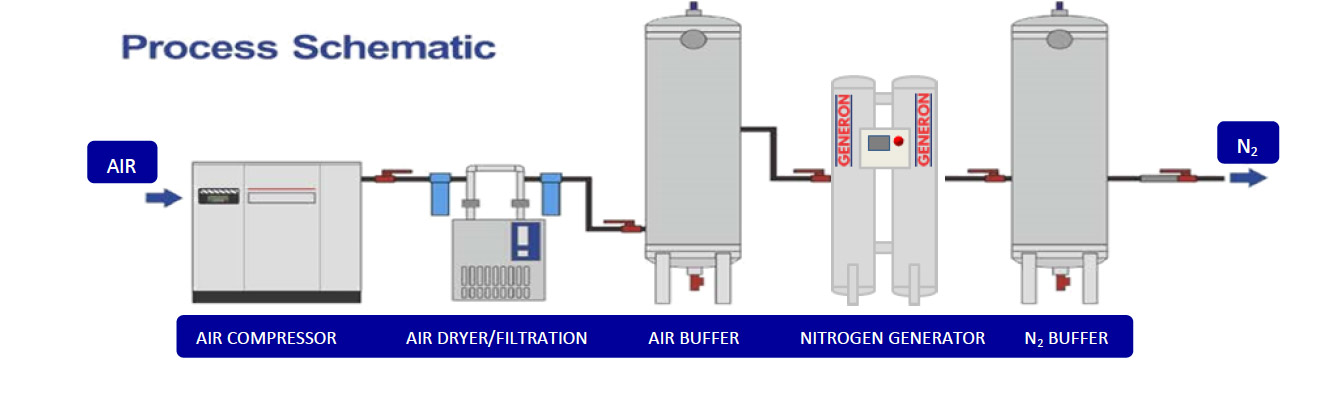

GENERON® Sequential PSA Nitrogen Generators separate nitrogen from compressed air utilizing Pressure Swing Adsorption (PSA) technology. This product line is designed for medium to large flow rates and have a reduced footprint. It consists of multiple pairs of our Twin Tower Adsorber Vessels and operates on alternating cycles.

Standard Features:

- ASME Adsorber Vessels

- High Cycle Life Pneumatic / Electric Valves

- Oxygen Analyzer (with calibration kit)

- Pressure Safety Valve

- Nitrogen Pressure Regulator

- PLC Control System

- Carbon Steel Skid

- Exhaust Silencing Muffler

- Highest Performance Adsorbent Media

- Low Overall Height for Compact Area

Options / Upgrades:

- Inlet Filtration Package

- Post Filtration Package

- Product Flow Meter

- Auto Shut Down/Startup/Standby mode

- Off Specification Circuit

- Compressed Air Buffer Tank

- Nitrogen Buffer Tank

- Master Controller driven for multiple unit operation

- Enhanced PLC with Telemetry

- HMI Display Screen

- Dew Point Analyzer

- Energy Saving Part-Load Control

Advantages:

- Low Gas Generating Cost

- Low Energy Consumption

- Fully Automatic Unattended Operation

- Highly Reliable

- Easy Installation

- Low Maintenance

- Heavy Duty Construction

- No Hazardous Storage

- Low dBa Levels

| PARAMETERS | Dimensions: | 116″ – 240″ L x 96″ W x 108″ H |

| Weight | 8,000 – 45,000 lbs | |

| Power Requirement: | 900 – 1,500 WATT @ 120 VAC Supply | |

| Inlet Air Connection: | 3″ – 6″ 150# RF | |

| N2 Outlet Connection: | 2″ – 4″ 150# RF |

| Nitrogen Purity / Flow Rate | ||||||||||||

| Model | psig | barg | 97% | 99% | 99.90% | 99.99% | 99.999% | |||||

| Size | scfm | Nm3/h | scfm | Nm3/h | scfm | Nm3/h | scfm | Nm3/h | scfm | Nm3/h | ||

| 2xNS-20-65 | 90 to 145 | 6.2 to 10 | 171-292 | 271-463 | 126-207 | 200-329 | 72-108 | 115-171 | 49-58 | 77-93 | 25-21 | 41-33 |

| 2xNS-24-64 | 90 to 145 | 6.2 to 10 | 246-420 | 390-665 | 181-298 | 288-472 | 104-155 | 165-246 | 70-84 | 111-133 | 37-30 | 59-48 |

| 2xNS-30-56 | 90 to 145 | 6.2 to 10 | 341-582 | 541-922 | 252-413 | 399-654 | 144-215 | 229-341 | 98-117 | 155-185 | 51-42 | 81-66 |

| 2xNS-36-56 | 90 to 145 | 6.2 to 10 | 496-846 | 786-1340 | 366-600 | 579-951 | 210-313 | 333-495 | 142-170 | 225-269 | 75-61 | 118-97 |

| 3xNS-36-56 | 90 to 145 | 6.2 to 10 | 745-1269 | 1179-2010 | 549-901 | 869-1427 | 315-469 | 500-743 | 213-255 | 338-404 | 112-92 | 178-146 |

| 4xNS-36-56 | 90 to 145 | 6.2 to 10 | 993-1692 | 1572-2680 | 732-1201 | 1159-1902 | 421-626 | 666-991 | 284-340 | 450-539 | 150-122 | 237-194 |

| 5xNS-36-56 | 90 to 145 | 6.2 to 10 | 1241-2116 | 1965-3350 | 915-1502 | 1449-2378 | 526-783 | 833-1239 | 356-425 | 563-673 | 187-153 | 297-243 |

| 10xNS-36-56 | 90 to 145 | 6.2 to 10 | 2483-4232 | 3931-6700 | 1831-3004 | 2899-4757 | 1052-1566 | 1666-2479 | 712-851 | 1127-1347 | 375-307 | 594-486 |

| Flow and pressure values are averages throughout a cycle with tolerances of ±4%. Performance data based on 68°F (20°C) PSA inlet temperature. Standard conditions: 68°F (20°C) and 14.696 psi (1 atm). Custom sizes are available upon request. | ||||||||||||