Oxygen Membrane Modules

GENERON® is an industry leader in the design and manufacture of Hollow Fiber Membrane Modules for the separation of Air Gases and Process Gases. The company has been manufacturing Hollow Fiber Membrane Modules for over 50 years and has over 100,000 units in operation in Petrochemical, Environmental, Industrial, Marine, Aircraft and Oil & Gas applications.

GENERON® Hollow Fiber Membrane Modules are manufactured in the Pittsburg, California, USA manufacturing facilities.

GENERON® Oxygen Membrane Modules are used in GENERON® Oxygen Generators, as well as supplied to approved OEM’s for use in their proprietary systems.

Technology and Operation

GENERON® offers multiple types of Membrane modules, depending on the final product application. Each application design has a unique chemical formulation and production process for the individual module fibers.

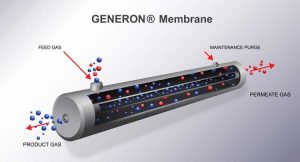

At the heart of the technology are polymeric membrane materials that allow for rapid passage of a single gas, while minimizing the passage of others, when applying a pressure gradient across the membrane.

Membrane materials are formed into hollow fibers to provide a maximum surface area, for the high gas flow often required. GENERON® holds over 100 U.S. patents on the design, packaging, and formulation of these hollow fiber oxygen membranes. The fibers are bundled into modules of various lengths and diameters to meet very specific flow rates and separation applications. Typical modules have anywhere from a half a million, to over a million fibers in one bundle.

Membrane materials are formed into hollow fibers to provide a maximum surface area, for the high gas flow often required. GENERON® holds over 100 U.S. patents on the design, packaging, and formulation of these hollow fiber oxygen membranes. The fibers are bundled into modules of various lengths and diameters to meet very specific flow rates and separation applications. Typical modules have anywhere from a half a million, to over a million fibers in one bundle.

The process works by compressed air being directed down the center of the module fibers. As the compressed air passes down the fiber, Oxygen molecules pass through the wall of the fiber and Nitrogen molecules continue down the hollow fiber and exit at the opposite end. The separation process is quite simple and involves no moving parts, making this process ideal for applications of Oxygen purity of 38.5% or less.