Membrane Dryers

GENERON provides a full range of Instrument Air Packages. These packages can be unitized with Primary Air Compression to reduce the overall package size and installation cost and time. GENERON® Membrane systems are compact and virtually maintenance free.

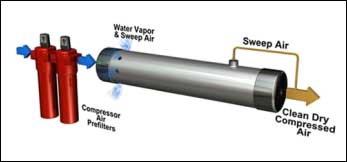

The compressed air, saturated with water vapor, flows through a bundle of GENERON® hollow-fiber membranes. The GENERON® Membranes allow water vapor to pass while the air remains and discharged as a dry product. A fraction of the dry air is redirected internally to sweep the permeated water vapor out of the module.

The compressed air, saturated with water vapor, flows through a bundle of GENERON® hollow-fiber membranes. The GENERON® Membranes allow water vapor to pass while the air remains and discharged as a dry product. A fraction of the dry air is redirected internally to sweep the permeated water vapor out of the module.

GENERON® Membrane Dryers perform with the lowest purge air loss for the highest possible efficiency—saving you time and money in the production process.

Over 50 years of Manufacturing and Engineering

![]() GENERON® Membranes have been the benchmark of the industry and proud to have shipped over 100,000 membranes around the world.

GENERON® Membranes have been the benchmark of the industry and proud to have shipped over 100,000 membranes around the world.

![]() Save Energy

Save Energy

GENERON® Membrane modules offer the highest efficiency in the market, reducing your compression cost.

![]() Reduced Footprint

Reduced Footprint

GENERON® Membrane modules have the highest productivity in the industry and can have a 30% smaller footprint, allowing for horizontal or vertical installation, and adaptable to any space requirement.

![]() Easy Start-Up

Easy Start-Up

GENERON® Systems are delivered ready to start and deliver dry air.

![]() Suited for Tough Environments

Suited for Tough Environments

GENERON® Membrane modules are built to withstand even the roughest operating conditions, including the harsh off-shore environment.

![]() Quality is Guaranteed

Quality is Guaranteed

Every GENERON® Membrane module is rigorously tested to the highest-standards in one of our ISO-9001 certified facilities.

FEATURES:

- .01 Micron Coalescing Filter with drain

- Activated Carbon Filter

- GENERON® Hollow Fiber Membranes

- PLC Control System with HMI Feature

- NEMA 12 Cabinet Enclosure

- Inlet Pressure Gauge

- Outlet Pressure Gauge

- Pressure Safety Valve

- System Lifting lugs

- Performance Test and Report

- Performance certificate

OPTIONS

- Demister / Moister Separator

- 1 Micron Coalescing Filter

- Process Heater

- Automatic Purity Control Valve

- NEMA 4X Control Cabinet Enclosure (316SS)

- Enhanced PLC with Telemetry

- Hazardous Area Classification

- Auto/Standby Mode

- Product Flow Meter

- Dew Point Analyzer

- Primary Air Compression

Technical Data

Available Designs

Cabinet Series

Skid Series

Container Series

GENERON Related Products:

- Primary Air Compression Packages

- Instrument Air Packages

- Process Skids-CH4/CO2 Separations

- Gas Dehydration Systems

- Fuel Conditioning Skids

- Nitrogen Generators from 95 to 99.999% Purities.

- Gas Booster Compression Packages

- High Pressure Bottle Filling Packages