Marine News

June 26, 2019

Generon IGS, Inc. has shipped the first three (3) shipsets against the supply contract for 4+2+2 of membrane-based nitrogen generators with a capacity 4500 m3/h at 95% for 49,000 DWT Stainless Steel IMO II, III chemical and oil product tankers

IGS (Innovative Gas Systems) is the worlds leading manufacturer of Nitrogen Generators. We manufacture both, PSA Systems and Membrane Systems. Our membrane systems make use of the superior performance of our GENERON® membranes, manufactured in California, USA. And our performance in terms of nitrogen flow capacity and air efficiency got even better, just recently. Our PSA systems are state-of-the-art with the highest air efficiency out there and operated in sequential configuration to allow minimum footprint and weight.

We want to help you to decide on the right system type for your marine application. And at Generon you have the choice of a quality Membrane or PSA system made in the USA (GENERON IGS) or PSA made in China (SMC IGS).

In October 2017 Generon was awarded a contract for the supply of 4+2+2 Nitrogen Membrane Type shipsets with a design capacity of 4500 m3/h nitrogen at 95 Vol. % to Chinese shipyard Hudong. The first shipset is undergoing sea trail operation in July 2019.

The 49,000 DWT Stainless Steel IMO II,III Chemical and Oil Product Tankers will be delivered to Norwegian Owner Odfjell over a 3-year time frame.

During the bidding stage, both the owner and the yard have gone through a detailed evaluation regarding the benefits of Membrane and PSA technology for this application.

Utilizing our newly developed GENERON® CP High Flow & Efficiency Membrane Type along with premium and innovative Tamrotor Marine Air Compressor and Dryer Solutions it was proven that the Membrane Package offered substantial weight and footprint benefits at the same power consumption and overall cost.

Generally, both PSA and Membrane Systems are used to generate nitrogen onboard ships. PSA technology was used before membrane technology was invented. Nowadays membrane Systems are by far the most commonly used technology, due to significant space and maintenance advantages and the increasing efficiency advantage over the PSA with rising operating temperatures.

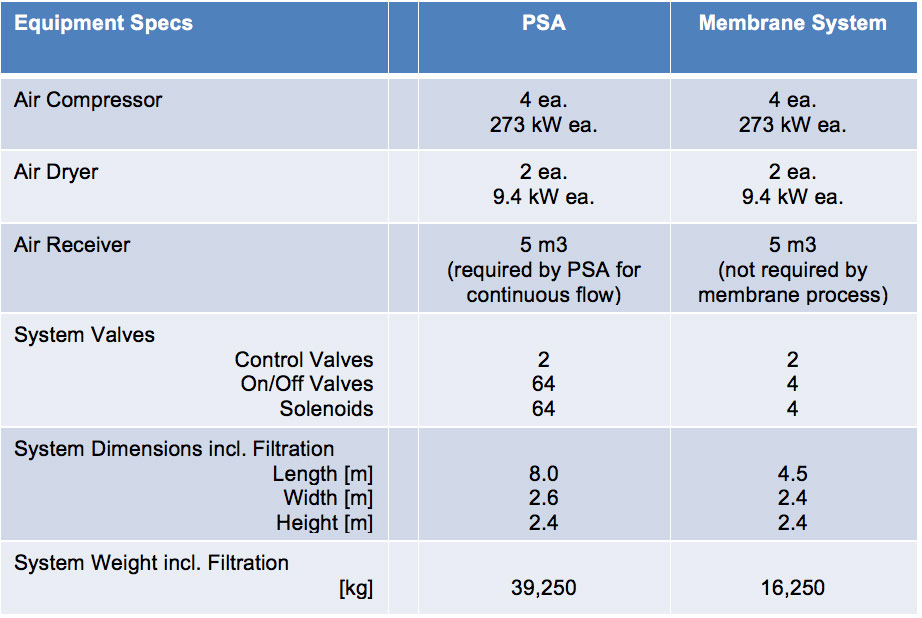

The below summary of comparison and fact check is valid for any flow of nitrogen

(100-5000 m3/h) at a design purity of 95% and a discharge pressure between 7-8 barg to the deck tank although for below we used the 4500 m3/h product flow with a 2 x 50% split system configuration:

The Advantages of a Membrane System over a PSA…

- A) Simplicity of Equipment and Operation:

With an identical or slightly lower air consumption over the PSA, the Membrane System uses the identical number of air compressors and air dryers. The air receiver is a luxury for the membrane system, but a necessity for the PSA to buffer the fluctuating air demand. The pre-filtration is identical between the two technologies and port-filtration is not required for the membrane system. Due to the use of an air dryer, both technologies do not require a process heater, which can lead to ground fault alarms onboard ships. With only 4 on/off valves to realize the 2 x 50% split, the membrane system is by far easier to control, operate and maintain if compared to the PSA with 64 valves. - B) Utility Consumption

The total power and cooling water consumption is identical for the same N2 output purity of 5%.C) Installation Dimensions

The Membrane generator occupies only about 40-60% of the footprint that a PSA uses. This is precious space in the crowded machine or utility room that can be utilized for additional food storage or other important items. - D) Weight Savings:

A huge amount of weight can be saved when using a Membrane over a PSA. The new patented cabinet design of Generon is reducing the weight and footprint of membrane systems even further and adds up here to 23,000 kg between the two types of nitrogen generators. This lower mass allows for more cargo to be transported and over the lifetime of the ship a recognizable saving in fuel consumption and reduction of CO2 emissions. - E) Operating Purity

Both technologies will produce nitrogen from 95 Vol.-% during unloading of the cargo and up to 99,99% at a reduced flow rate for padding applications. - F) Lower Maintenance Cost

Lower maintenance cost on membrane system due to fewer moving parts (valves) and easier access to main generator devices are well known in the industry. With Generon’s new patented cabinet design, the accessibility and maintainability was even further improved. Both technologies require frequent bi-annual filter changes, but the membrane System does not require component overhauls, like the annual installation of valve seal-kits.

Generon IGS, 16250 Tomball Parkway, Houston, Texas 77086, USA

Phone: (713) 937-5200; Fax: (713) 937-5250, www.generon.com