Landfill Gas to Energy Systems – How Does Landfill Gas Collection Work?

September 10, 2019

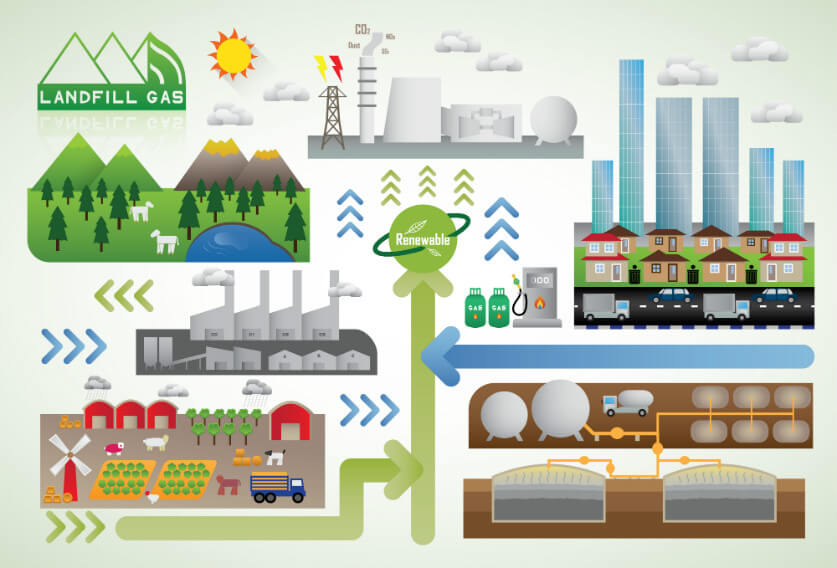

The need for renewable sources of energy has necessitated the exploration of various methods of power generation. Conversion of gaseous effluents from a landfill site to usable energy is an environmentally friendly means of achieving climate change goals.

This article will explain the vital question renewable energy enthusiasts ask: how does landfill gas work?

What Is Landfill Gas (LFG)?

Landfill gas is a mixture of various gases derived from the actions of microorganisms on the components of a landfill site. This gas forms when the refuse materials from a waste disposal site are subjected to physical and chemical processes coupled with microbial substance breakdown. These processes are

- Volatile compound evaporation

- Chemical interactions between waste products

- Microbiologic interactions (especially methanogenesis)

Typical Landfill Gas Composition

Landfill gas is mainly composed of methane gas (about forty to sixty percent) with carbon dioxide and other volatile organic compounds constituting the remainder. Microbes within a landfill gas collection and control system will breakdown the waste in a biomethanation reaction which releases large amounts of methane gas. Landfill gas collection systems seek to capture the generated methane to drive energy production processes.

Why Do We Bother with Landfill Gas?

As global warming concerns continue to plague the planet, it has become imperative that humans reduce the number of emissions we release into our environment. Additionally, landfill gas collection systems are designed to economically recycle waste gases to produce useful electrical energy and renewable natural gas for heating and other domestic purposes.

In regions with efficient landfill gas extraction systems, dependence on fossil fuels to drive energy production has been minimized significantly.

Landfill Gas to Energy Systems – How they Work

A series of well-ordered processes are involved in the conversion of methane gas from a landfill to usable energy. The steps in this sequence are outlined in the sections below.

Landfill Waste Collection and Compaction

The process of methane landfill gas extraction begins with the collection and compaction of waste. Various non-hazardous waste materials are collected at the landfill site and compacted into landfill pits known as cells which are then subsequently sealed off to allow decomposition and release of methane, carbon dioxide, and other volatile gases.

Landfill Gas Extraction Techniques

Accumulated landfill gas can be recovered from landfill cells using either horizontal trenches created within the cells, vertical wells sunk into the enclosed cell spaces (landfill drilling) or a combination of both recovery techniques.

Although the landfill gas collection designs that are installed in individual generation plants vary based on operator preferences, installation, and running cost considerations, horizontal and vertical methods will achieve similar rates of methane gas recovery.

Primary Landfill Gas Processing

Following landfill gas collection, the recovered methane gas is sent to primary processing which eliminates moisture and creates the necessary pressure needed to convey the gas to either an endpoint or to further treatment. Basic components of the primary process of methane extraction from landfills include:

- Knock-out drums for moisture removal

- Blowers which create a vacuum and pressure to convey gas

- Heat exchangers for process cooling

- Control unit for landfill gas monitoring which regulates vacuum, gas flow rate, and temperatures

- Landfill gas flare systems

Landfill Gas Energy Applications

There are several applications for extracted landfill gas which are categorized into three major groups for ease of understanding

- Electricity generation

- Modification to renewable natural gas

- Direct use in industrial manufacturing

How is Landfill Gas Turned into Electricity?

The majority of the landfill gas generated in the US is used in electricity generation. There are various ways that the recovered methane gas is converted to electrical energy including the methods listed below.

- Gas turbines

- Microturbines

- Fuel cells

- Reciprocating internal combustion engines

Generally, the most popularly employed method involves the use of reciprocating internal combustion engines which are cost-effective and highly efficient. Further, cogeneration, a process where heat and electricity are simultaneously generated can also be done using landfill gases.

Modification to Renewable Natural Gas

Landfill derived gas can be altered into natural gas by increasing its methane content while minimizing other component gases (carbon monoxide, nitrogen, and oxygen). The modified natural gas can be used to power vehicles and generate electricity.

Direct Use in Industrial Manufacturing

In a non-modified form, landfill gases can be employed various thermal and combustion applications. Landfill methane can be utilized in greenhouses, boilers, and kilns. For example, the Star Ridge Landfill in Moody, AL produces around 900 CFM of landfill gas via pipeline to the kiln of a nearby brick manufacturer.

LFG Landfill Gas Treatment

Depending on the energy generation purpose for which the methane gas from landfills is intended, it will require added treatment to remove impurities and moisture. Typically, treatment towers and filters are used to remove water, hydrogen sulfide, siloxanes, and carbon monoxide and facilitate landfill gas treatment.

Contact GENERON for Your LFG Conditioning Needs

For over four decades, GENERON has been dedicated to providing a robust selection of highly effective technologies optimized for various industrial energy production processes including landfill gas conditioning units.

For more information about LFG conditioning services we offer, contact GENERON today!