What Is Gas Sweetening?

June 11, 2019

Before natural gas or landfill gas can be injected into a pipeline or used in commercial applications such as CNG, Power Generation, etc. it must meet specific requirements for quality. Natural gas or landfill gas can be sweet or sour depending on the level of contaminants present. Sweet gas is favorable for transport and sale as it has the required heating value, while sour gas must be sent for further refining.

What Is Sour gas?

Sour gas is natural gas containing Hydrogen Sulfide (H2S) levels greater than 5.7 mg or 4 ppm (parts per million) by volume under standard temperature and pressure conditions. This value, however, varies between countries and regions.

The term ‘acid gas’ is often used interchangeably with sour gas, but they do not mean the same thing. Acid gas is natural gas that contains a high level of acidic gases, e.g., CO2 and H2S. In addition to H2S, acidic gas may also contain contaminants such as Carbon Dioxide (CO2) and Nitrous Oxides (known environmental pollutants). To regulate emissions and the release of toxic gases, authorities mandate natural gas producers to minimize the Sulfuric content in their products. Therefore, sour gas must be sweetened before it is sent out from the refinery or gas processing plant.

What Is Sweet Gas?

Natural gas or landfill gas can be termed ‘sweet gas’ if it contains only trace quantities of H2S and CO2. Sweet gas in its pure form is non-corrosive, requires little refining, and we can transport and market it safely.

What Is Gas Sweetening?

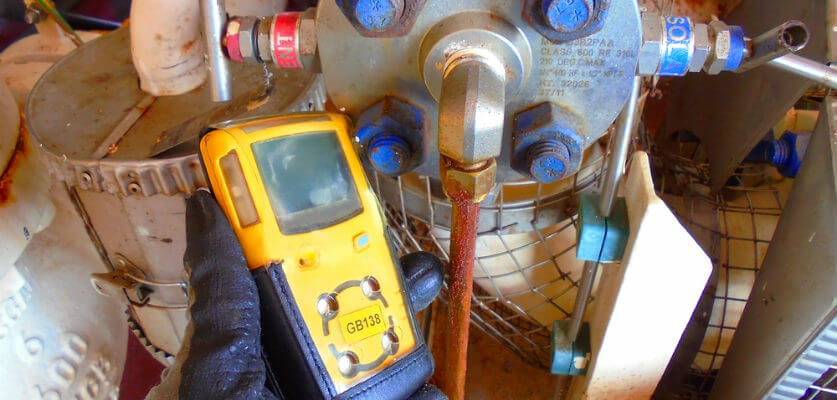

Gas sweetening is the process of removing Hydrogen Sulfides, Carbon Dioxide, and Mercaptans from natural gas to make it suitable for transport and sale. Sour gas must be sweetened because H2S and CO2 have a corrosive effect on gas pipelines and are also toxic to humans.

Types of Gas Sweetening Techniques

There are several methods for gas sweetening. Industries can choose from a range of solutions based on efficiency, cost, scale, and space considerations.

The most effective gas sweetening process uses a membrane with pre-treatment that is designed based on Feed gas composition.

Sour Gas Sweetening with Membrane Technology

Membrane technology can be used to separate water vapor, H2S, and CO2 at lower concentration levels in natural gas streams, natural gas liquids (NGLs), and liquefied petroleum gas (LPG). Natural gas sweetening with membranes may utilize several columns for effective separation and automated sequencing to achieve continuous operation.

Cost-Effective & Efficient Natural Gas Sweetening with GENERON

GENERON systems for CO2 removal from natural gas offer high selectivity for Carbon dioxide and Methane for optimum recovery of pure natural gas. GENERON® membrane modules filter the feed gas to efficiently separate CO2 and H2S from methane post-filtration. We also offer cost-effective, customized solutions to suit individual clients’ needs.

For Natural Gas sweetening systems/services contact GENERON today!