Coal Bed Methane Treatment

Coal bed methane gas is present in coal deposits and mainly consists of CH4 and CO2. The simplest way to treat is with GENERON‘s® membrane technology that lowers the CO2 content to less then 2 mol %.

GENERON‘s® membrane systems have been used to reduce the CO2 and improve the heating value of the gas. GENERON supplies customized coal bed methane gas treatment systems which also include the feed compression. GENERON® fabricates its own membrane filters and works directly with the client to provide the most cost effective solution.

Alternatives for treating the coal bed methane gas are amine systems which are complex and have high capital, operating and installation costs, as well as requiring chemicals that need continued replacement and disposal.

Other alternatives for biogas treatment are adsorption (water wash) or adsorption (PSA) systems. These complex systems have high capital, operating and installation cost compared to membrane systems.

The GENERON® Advantage

- Extensive Experience – custom designed skids

- State-of-the-art Membrane – high recoveries

- Simple Solution – no moving parts, minimal maintenance

- Remote Operation – Minimal attention required, fully automated systems

- Minimal Losses – low HC losses

- No Chemicals – environmentally friendly

- Small Footprint – easily meet footprint requirements

RELATED GENERON PRODUCTS:

RELATED GENERON PRODUCTS:

- PSA systems

- Instrument air packages

- Air and gas compression packages

- Blowers

- On-site oilfield services – operating personnel and rental equipment

- Custom Integrated Skid Packages

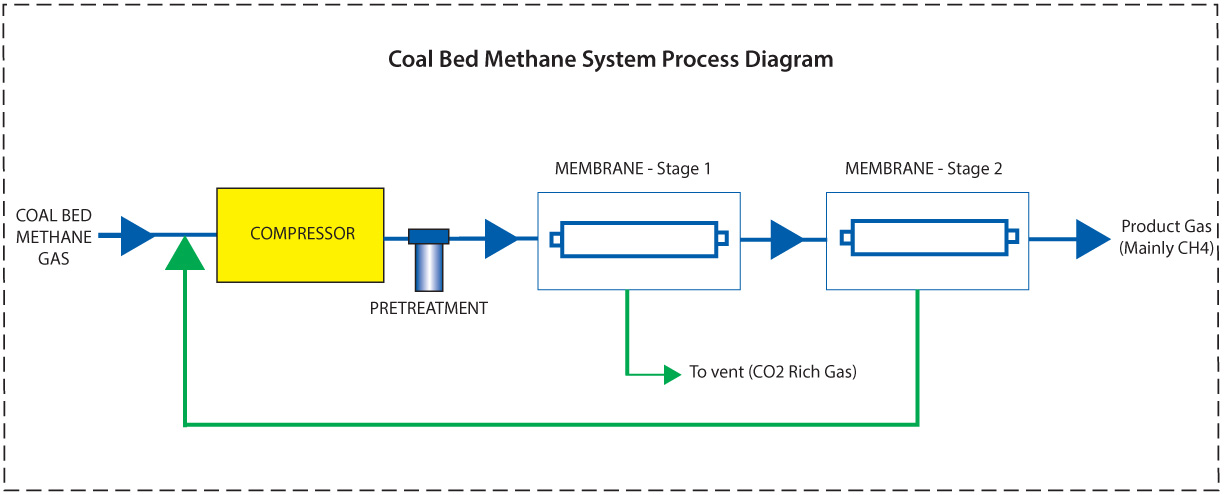

In a typical GENERON® coal bed methane treatment membrane system the feed gas is first filtered to remove any particles and liquid condensate. The gas then enters the GENERON® membrane filters. The CO2 permeates preferably through the membrane. The non-permeated gas, mainly CH4, remains at pressure and is the product gas.

SYSTEM PERFORMANCE

SYSTEM PERFORMANCE

- Feed gas pressures down to -100” H2O

- > 60 vol% CO2 in feed

- < 2% CO2 content in product

- > 98% recovery of methane gas

- > 98% removal of CO2

- Flow rates to 50 MMSCFD

ADVANTAGES

- No moving parts, and designed for remote unmanned operation

- Efficient packaging minimizes space and weight – ideal for offshore applications

- Optimized process design to maximize total hydrocarbon recovery

- System flexibility – Can operate at wide range of flow rates and CO2 Content

- Quick deployment & quick Installation – skidded system can be installed in hours

SYSTEM PERFORMANCE

SYSTEM PERFORMANCE