PSA Oxygen Generator

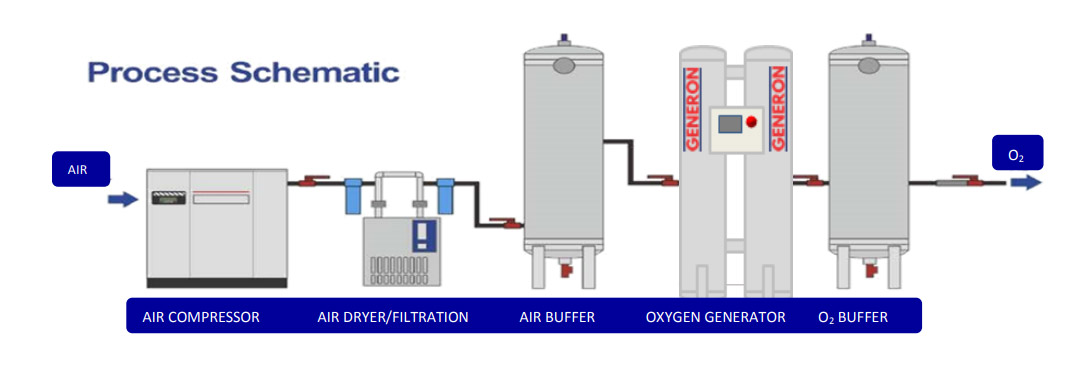

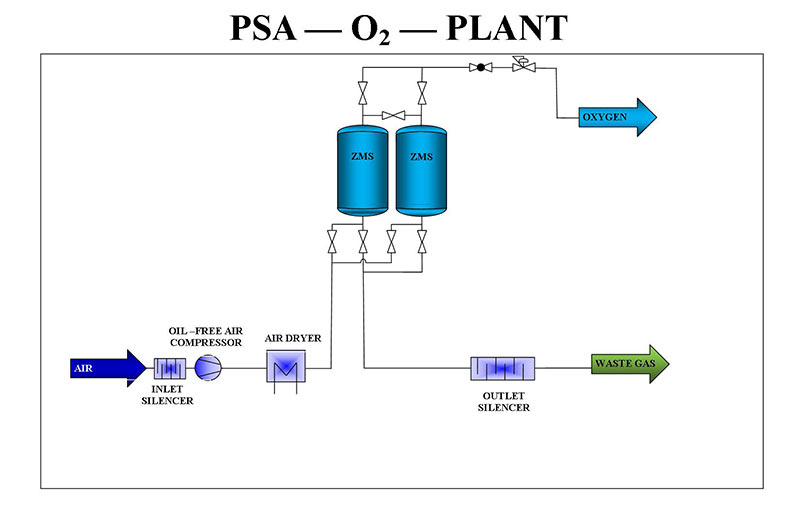

GENERON® Oxygen PSA Generators separates oxygen (O2) from compressed air utilizing pressure swing adsorption technology. Compressed air, which consists of approximately 21% oxygen and 78% nitrogen, is passed through a bed of zeolite molecular sieve (ZMS). The sieve preferentially adsorbs N2 and moisture over O2 allowing the O2 to pass through as a product gas at pressure. While one of the towers is in the adsorption phase the other tower is regenerated by de-pressurizing, at which time the sieve releases the adsorbed gases to the atmosphere, and the cycle is then repeated. A solid state programmable controller operates the process valves on an alternating cycle, with built-in logic for automatic stop/start. Oxygen flow and purity remain constant regardless of the peak usage demands. Under normal operating conditions and with correct maintenance the zeolite molecular sieve will have an almost indefinite lifetime.

GENERON® Oxygen PSA Generators separates oxygen (O2) from compressed air utilizing pressure swing adsorption technology. Compressed air, which consists of approximately 21% oxygen and 78% nitrogen, is passed through a bed of zeolite molecular sieve (ZMS). The sieve preferentially adsorbs N2 and moisture over O2 allowing the O2 to pass through as a product gas at pressure. While one of the towers is in the adsorption phase the other tower is regenerated by de-pressurizing, at which time the sieve releases the adsorbed gases to the atmosphere, and the cycle is then repeated. A solid state programmable controller operates the process valves on an alternating cycle, with built-in logic for automatic stop/start. Oxygen flow and purity remain constant regardless of the peak usage demands. Under normal operating conditions and with correct maintenance the zeolite molecular sieve will have an almost indefinite lifetime.

PSA Oxygen Generators Operating Principle

The PSA Oxygen Generator works the same as our Nitrogen PSA Generators with one exception. The adsorption media inside the vessel for an Oxygen PSA is a material called a Zeolite, for a Nitrogen PSA the material is called CMS (Carbon Molecular Sieve). In both cases compressed air is fed into one of the absorption towers. In the case of an Oxygen generator the Nitrogen in the Air is absorbed onto the Zeolite surface and the Oxygen passes out of the vessel at the desired purity. Once the Zeolite absorption material become saturated with Nitrogen the compressed air is switched to the other vessel which now does the absorption while the other vessel is regenerated.

The Zeolite material have a very unique property that when the pressure is released back to atmospheric pressure during the regeneration process the Zeolite releases the Nitrogen that was stored on its surface. The process consists of switching the compressed air from one vessel to the other by means of a series of valves in a very precise sequence to take advantage of this unique property.

This process provides a constant flow of Oxygen for a multitude of applications.

Typical Applications

- Fish farming

- Sewage treatment

- Glass industry

- Food industries

- Pulp and paper industry

- Welding, melting, brazing

- Manufacturing batteries

- Chemical oxidation

Advantages of GENERON® OXYSWING PSA

- Low operating pressures

- No hazardous storage or connections

- Low gas generating costs

- Fully automatic unattended operation

- High life cycle valves

- Easy to install and maintain • Low dBA levels

Standard Components:

- ASME adsorber vessels

- High life cycle valves

- Oxygen analyzer (with calibration kit)

- Piping, gauges, and instrumentation

- Pressure Safety valve

- Oxygen flow regulators

- PLC control system

- Carbon Steel skid mounted

- Exhaust silencing muffler

Options:

- Product flow meter

- Inlet filtration package

- Post filtration package

- Auto shut down/startup/standby mode

- Off specification circuit

- HMI Display Screen

- Master controller: PLC driven for multiple unit operation

- Enhanced PLC with telemetry

- Compressed air buffer tank

- Oxygen buffer tank

- Product booster compressor

- Dew point analyzer

- Tanks & generator on a common skid

PSA O2 Generator Product Offerings

| OXYGEN PURITY / FLOW RATE | ||||||||

| PSA

MODEL |

90% | 93% | APPROX. WEIGHT AND DIMENSIONS | |||||

|

SCFH |

NM3/HR |

SCFH |

NM3/HR |

H | W | L | WEIGHT | |

| Inch | Inch | Inch | Lbs. | |||||

| OS-8-60 | 73 | 1.92 | 65 | 1.71 | 86 | 36 | 30 | 720 |

| OS-10-60 | 111 | 2.93 | 100 | 2.62 | 87 | 36 | 37 | 780 |

| OS-12-60 | 164 | 4.31 | 147 | 3.86 | 87 | 42 | 48 | 1728 |

| OS-14-66 | 207 | 5.44 | 185 | 4.86 | 93 | 42 | 48 | 1927 |

| OS-16-75 | 311 | 8.19 | 278 | 7.32 | 103 | 46 | 48 | 2630 |

| OS-18-78 | 414 | 10.89 | 371 | 9.74 | 106 | 50 | 53 | 4892 |

| OS-20-78 | 516 | 13.57 | 461 | 12.13 | 110 | 52 | 58 | 3851 |

| OS-24-75 | 724 | 19.03 | 647 | 17.02 | 97 | 54 | 60 | 4592 |

| OS-30-81 | 1237 | 32.52 | 1106 | 29.10 | 121 | 72 | 72 | 7576 |

| OS-36-74 | 1641 | 43.15 | 1468 | 38.60 | 116 | 74 | 88 | 9370 |

| OS-36-95 | 2107 | 55.40 | 1885 | 49.56 | 137 | 74 | 88 | 10882 |

| OS-42-83 | 2521 | 66.28 | 2255 | 59.29 | 135 | 84 | 112 | 15238 |

| OS-48-74 | 2918 | 76.72 | 2610 | 68.63 | 127 | 90 | 112 | 15602 |

| OS-48-94 | 3706 | 97.45 | 3315 | 87.18 | 147 | 90 | 112 | 16699 |

| OS-60-68 | 4101 | 107.83 | 3668 | 96.46 | 121 | 120 | 156 | 19988 |

| OS-60-74 | 4473 | 117.63 | 4002 | 105.23 | 127 | 120 | 156 | 20791 |

| OS-60-81 | 5033 | 132.33 | 4502 | 118.38 | 184 | 120 | 156 | 21774 |

| The nominal rating of the generators are at 68°F; 0% RH and at 14.5 Psia. Flow and pressure values are averages throughout a cycle with tolerances of ± 4%. Purity values are ± 2%. Performance based on Inlet pressure of 109 PSIG (7.5barg). | ||||||||